The Tuff Torq K46 transmission is a reliable hydrostatic unit designed for durability and performance in various tractors and mowers. Regular maintenance, including fluid checks and lubrication, ensures optimal functionality. The service manual provides essential guidelines for upkeep, repair, and troubleshooting, making it a vital resource for owners. Proper oil management and reassembly tips are also highlighted to maximize the transmission’s lifespan and efficiency.

1.1 Overview of the Tuff Torq K46 Model

The Tuff Torq K46 transmission is a hydrostatic unit designed for durability and performance in various tractors and mowers. It is known for its compact design and compatibility with multiple vehicle models, including Husqvarna and John Deere lawn tractors. The K46 model features an internal reservoir for transmission fluid, which simplifies maintenance and ensures consistent lubrication. While it is built to last, regular servicing, such as checking oil levels and lubricating mating surfaces, is crucial to maintain optimal performance. The service manual provides detailed instructions for these tasks, ensuring users can keep their transmission running smoothly. Proper care extends the lifespan and reliability of the K46, making it a trusted choice for outdoor equipment.

1.2 Importance of the Service Manual

The Tuff Torq K46 service manual is an essential resource for maintaining, troubleshooting, and repairing the transmission. It provides detailed instructions for regular maintenance tasks, such as fluid checks and lubrication of mating surfaces, ensuring optimal performance. The manual also includes troubleshooting guides for common issues like overheating or slipping, offering practical solutions to restore functionality. Additionally, it outlines repair tips, such as cleaning and flushing the transmission, and proper part inspection during reassembly. By following the manual’s guidelines, users can extend the lifespan of the K46 transmission and prevent costly repairs. It is a vital tool for both professionals and DIY enthusiasts, ensuring safe and effective servicing of the unit.

Key Features of the Tuff Torq K46 Transmission

The Tuff Torq K46 transmission features a durable hydrostatic design, internal oil reservoir, and compatibility with Husqvarna and John Deere tractors. It requires 5W-50 synthetic oil for optimal performance.

2.1 Design and Construction

The Tuff Torq K46 transmission is a hydrostatic unit designed for durability and performance. Its compact design integrates an internal oil reservoir, eliminating the need for external fluid systems. Constructed with robust materials, it ensures reliability under various operating conditions. The transmission features a sealed system, minimizing contamination risks and reducing maintenance needs. Hydrostatic technology provides smooth power delivery, essential for mowing and heavy-duty tasks. Compatibility with Husqvarna and John Deere tractors highlights its versatility. The K46’s internal components are engineered for efficient lubrication, requiring 5W-50 synthetic oil for optimal performance. Proper assembly and lubrication of mating surfaces during repairs are critical to maintain functionality and longevity.

2.2 Compatibility with Various Tractors and Mowers

The Tuff Torq K46 transmission is widely compatible with numerous tractor and mower models, including popular brands like Husqvarna and John Deere. Its versatility makes it a preferred choice for a variety of applications, from residential lawn care to commercial landscaping. Designed to integrate seamlessly with existing machinery, the K46 ensures smooth operation and optimal performance. Compatibility extends across different horsepower ranges, catering to diverse user needs. This adaptability contributes to its popularity among tractor and mower owners seeking reliable hydrostatic transmission solutions. The service manual provides detailed specifications to ensure proper installation and operation across compatible models, enhancing overall user satisfaction and equipment longevity.

Maintenance and Service Recommendations

Regular fluid checks and changes are crucial for the K46 transmission’s longevity. Cleaning and lubricating mating surfaces ensure smooth operation. Proper part inspection during reassembly is essential for reliability.

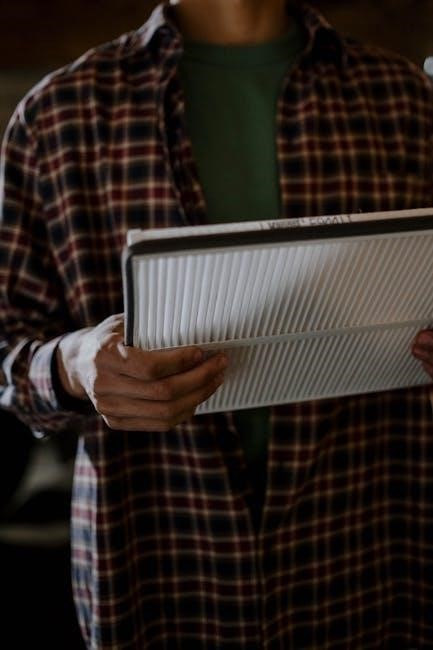

3.1 Regular Fluid Checks and Changes

Regular fluid checks and changes are essential for maintaining the performance and longevity of the Tuff Torq K46 transmission. The service manual recommends checking the oil level using the fill port under the black cap. Ensure the transmission is on a level surface and the oil level is at the designated mark. Draining and refilling the fluid every 100 hours of operation is advised to prevent contamination and wear. Always use the recommended 5W-50 synthetic oil to maintain optimal lubrication and performance. Avoid using ATF, as it is not compatible with the K46 transmission. Proper fluid management prevents overheating, slipping, and premature wear. Regular maintenance ensures smooth operation and extends the lifespan of the unit. Consult the manual for detailed instructions on fluid changes and level checks.

3.2 Lubrication Tips for Mating Surfaces

Proper lubrication of mating surfaces is critical for the smooth operation of the Tuff Torq K46 transmission. Always coat these surfaces with a thin layer of the recommended 5W-50 synthetic oil before reassembly. This ensures optimal lubrication and prevents excessive wear. Avoid using ATF, as it is not compatible with the K46 transmission. When reinstalling components, ensure all parts are clean and free of debris to maintain proper contact and functionality. Refer to the service manual for specific instructions on lubricating gears, bearings, and other critical areas. Proper lubrication reduces friction, prevents overheating, and extends the lifespan of the transmission. Regular inspection of mating surfaces during maintenance can help identify potential issues early, ensuring reliable performance.

Oil and Fluid Management

Regular fluid checks and changes are vital for the K46 transmission. Use 5W-50 synthetic oil for optimal performance. Models with internal reservoirs typically require no servicing. Avoid ATF.

4.1 Checking the Oil Level in the K46 Transmission

Checking the oil level in the Tuff Torq K46 transmission is straightforward but essential for maintaining its performance. Start by ensuring the transmission is warm, as this ensures accurate readings. Locate the fill port, typically marked with a black cap, and remove it to access the oil level. Use a clean rag to wipe the dipstick or oil level indicator before inserting it into the port. Pull it out and check the oil level against the recommended mark. The oil should be at the midway point between the “MIN” and “MAX” lines. If the level is low, add the recommended 5W-50 synthetic oil. Avoid overfilling, as this can damage the transmission. Always refer to the service manual for specific guidance tailored to your K46 model.

4.2 Recommended Oil Type (5W-50 Synthetic Oil)

The Tuff Torq K46 transmission requires the use of 5W-50 synthetic oil for optimal performance and longevity. This oil type is specifically designed to provide superior lubrication and temperature stability, ensuring smooth operation under various conditions. Synthetic oil offers better viscosity retention and wear protection compared to conventional oils, which is critical for hydrostatic transmissions. It is important to avoid using alternative oils, such as ATF, as they are not compatible with the K46 and may cause damage. Always refer to the service manual for confirmation of the recommended oil type. Proper oil selection ensures the transmission operates efficiently, reduces the risk of overheating, and extends its service life. Adhering to Tuff Torq’s guidelines is essential for maintaining warranty validity and ensuring reliable performance.

4.3 Draining and Refilling the Transmission Fluid

Draining and refilling the transmission fluid in the Tuff Torq K46 is a straightforward process that should be performed as part of regular maintenance. To drain the fluid, locate the fill port, typically under a black cap, and invert the transaxle to allow the oil to flow out completely. Once drained, refill the transmission with the recommended 5W-50 synthetic oil to ensure optimal performance and lubrication. Avoid using ATF or other non-recommended oils, as they may damage the transmission. Tuff Torq suggests draining and refilling the fluid every 100 hours of operation, starting with the first 50 hours. Always consult the service manual or contact Tuff Torq customer support for specific guidance to ensure the process is done correctly and safely.

Troubleshooting Common Issues

The Tuff Torq K46 transmission may experience overheating, slipping, or noise during operation. These issues often result from inadequate fluid levels, contamination, or worn components. Regular maintenance and inspections can help identify and address problems early, ensuring smooth functionality and extending the transmission’s lifespan. Always refer to the service manual for specific diagnostic steps and solutions tailored to the K46 model.

5.1 Overheating Problems and Solutions

Overheating is a common issue in the Tuff Torq K46 transmission, often caused by low fluid levels, contamination, or excessive workload. To address this, ensure the transmission fluid is at the recommended level and free from debris. Regularly flushing and replacing the fluid with 5W-50 synthetic oil can help maintain optimal temperatures. Additionally, check for blockages in the cooling system and ensure proper ventilation around the unit. If overheating persists, inspect for worn or damaged components and replace them as needed. Refer to the service manual for detailed diagnostic steps and solutions. Proper maintenance can prevent overheating and extend the transmission’s lifespan. Always follow Tuff Torq’s guidelines for fluid management and system care to avoid operational disruptions.

5.2 Slipping or Lack of Engagement

Slipping or lack of engagement in the Tuff Torq K46 transmission can occur due to low fluid levels, contaminated fluid, or worn clutch packs. To resolve this, first, check the transmission fluid level and top it off if necessary. Ensure the fluid is clean and free from debris; if contaminated, drain and replace it with 5W-50 synthetic oil. Inspect the clutch packs for wear and replace them if damaged. Additionally, verify that the control lever and linkage are functioning correctly and adjusted properly. If issues persist, consult the service manual for further diagnostic steps or contact Tuff Torq customer support for assistance. Regular maintenance and prompt repairs can prevent further damage and restore smooth operation. Always follow the manufacturer’s guidelines for fluid type and replacement intervals to maintain optimal performance.

5.3 Noise or Vibration During Operation

Noise or vibration during operation in the Tuff Torq K46 transmission can indicate underlying issues such as low fluid levels, debris in the system, or worn components. To address this, first, check the transmission fluid level and ensure it is at the recommended level. If the fluid is dirty or degraded, drain and replace it with the specified 5W-50 synthetic oil. Inspect the internal components for wear or damage, such as clutch packs or bearings, and replace them if necessary. Proper lubrication of mating surfaces during reassembly is crucial to minimize noise. If vibrations persist, verify that the transmission is securely mounted and aligned with the tractor or mower. Consult the service manual for detailed diagnostic procedures and repair guidelines. Addressing these issues promptly can prevent further damage and restore smooth operation. Always follow Tuff Torq’s recommendations for maintenance and repairs.

Reassembly and Repair Tips

Ensure proper cleaning and flushing of the transmission before reassembly. Lubricate mating surfaces with recommended oil and verify torque specifications for all components. Refer to the service manual for precise guidance to ensure optimal performance and longevity.

6.1 Cleaning and Flushing the Transmission

Cleaning and flushing the Tuff Torq K46 transmission are critical steps during reassembly to ensure optimal performance. Begin by draining the old transmission fluid using the fill port located under the black cap. Invert the transaxle to allow the fluid to drain completely. Next, flush the system with clean, recommended oil to remove any debris or contaminants. Use a soft cloth to wipe down all surfaces and components, paying special attention to mating surfaces and internal parts. Proper cleaning prevents old debris from causing wear or damage during operation. After flushing, refill the transmission with the specified 5W-50 synthetic oil to ensure smooth engagement and longevity. Always refer to the service manual for detailed diagrams and instructions to avoid misalignment or damage during the process.

6.2 Proper Part Inspection and Installation

Inspection of all components is essential before reinstalling them in the Tuff Torq K46 transmission. Examine parts for wear, damage, or misalignment, ensuring they are free from debris. Use genuine Tuff Torq replacement parts to maintain reliability and performance. During installation, follow the torque specifications outlined in the service manual to prevent overtightening or misalignment. Lubricate mating surfaces with the recommended 5W-50 synthetic oil to ensure smooth operation and reduce friction. Proper alignment of components, such as the freewheel rod and bypass pin, is crucial for optimal functionality. Refer to the manual’s diagrams for correct orientation and installation sequences. Improper installation can lead to leaks, noise, or premature wear, so attention to detail is paramount. Always verify the torque specifications for each bolt and stud to ensure a secure and durable reassembly.

6.3 Torque Tips for Reassembly

Proper torque application is critical during the reassembly of the Tuff Torq K46 transmission to ensure all components are securely fastened. Use a torque wrench to apply the specified values outlined in the service manual. For most bolts and studs, a torque range of 10-12 ft-lbs is typical, but verify the manual for specific values. Over-tightening can damage threads or warp components, while under-tightening may lead to leaks or loose connections. Pay special attention to the torque specifications for the bypass pin and freewheel rod, as these are critical for smooth operation. Always refer to the manual’s torque chart for precise values, and ensure all fasteners are tightened in the recommended sequence to maintain structural integrity. Proper torque ensures long-term reliability and prevents premature wear on the transmission.

Aftermarket Support and Resources

Tuff Torq provides comprehensive aftermarket support, including customer service at 866-572-3441 and email assistance. Repair kits, manuals, and parts are readily available for K46, K57, K574, and T40 models.

7.1 Contacting Tuff Torq Customer Service

Tuff Torq offers dedicated customer support to address inquiries and concerns. Owners can reach their service team via phone at 1-866-572-3441 or email at customerservicetufftorq.com. This direct line ensures prompt assistance with repair kits, troubleshooting, and maintenance guidance. The customer service team is equipped to provide detailed information on parts, manuals, and service procedures, making it easier for users to maintain their K46 transmission effectively. Additionally, the official website offers resources and documentation, including service manuals and repair tips, to help users resolve issues independently. Regular communication with Tuff Torq’s support team can enhance the longevity and performance of the transmission, ensuring it operates at its best for years to come.

7.2 Availability of Repair Kits and Manuals

Tuff Torq provides comprehensive repair kits and manuals to support the maintenance and repair of the K46 transmission. These resources are designed to help users perform effective servicing and ensure optimal performance. The repair kits include essential components for common repairs, while the manuals offer detailed, step-by-step instructions. Both are available through Tuff Torq’s official website or authorized distributors, ensuring accessibility for all users. By utilizing these resources, owners can maintain their transmissions with confidence, adhering to manufacturer guidelines for longevity and reliability. Regular updates to these materials reflect Tuff Torq’s commitment to customer support and product durability, making them invaluable for anyone working with the K46 model.

User Experiences and Case Studies

Users report mixed experiences with the Tuff Torq K46, praising its reliability but noting occasional issues like overheating and fluid leaks. Real-world case studies highlight its durability in heavy-duty applications, with some transmissions lasting over 1,000 hours without major repairs. Proper maintenance, as outlined in the service manual, significantly enhances performance and longevity. Common issues, such as slipping or noise, are often resolved with timely fluid changes and part replacements. These experiences underscore the importance of adhering to manufacturer guidelines for optimal results.

8.1 Real-World Performance of the K46 Transmission

The Tuff Torq K46 transmission has demonstrated robust performance in various applications, particularly in Husqvarna lawn tractors. Users report it handles heavy-duty tasks effectively, with some units operating smoothly for over 1,000 hours without major issues. Proper maintenance, such as regular fluid changes and lubrication, significantly enhances its reliability. However, some users note that overheating and slipping can occur under extreme conditions. The transmission’s design ensures efficient power transfer, making it suitable for demanding mowing and mulching tasks. Real-world feedback highlights its durability, with many owners praising its consistent performance when serviced according to the manual’s guidelines. The K46’s ability to withstand rigorous use underscores its reputation as a dependable choice for outdoor equipment.

8.2 Success Stories from Repair and Maintenance

Many users have reported successful repairs and extended lifespan of the K46 transmission by adhering to the service manual’s guidelines. Proper cleaning, lubrication of mating surfaces, and timely fluid changes have been key to restoring performance. A common success story involves resolving overheating issues by ensuring adequate cooling and maintaining the recommended oil level. Some users highlighted the importance of following torque specifications during reassembly, which prevented further damage. By addressing slipping problems through fluid replacements and inspecting worn parts, owners have restored their transmissions to optimal functionality. These experiences emphasize the value of meticulous maintenance and adherence to Tuff Torq’s recommendations, resulting in years of reliable service and increased equipment productivity.

Safety Precautions During Service

Always wear protective gear, ensure the tractor is on level ground, and disconnect the power source before servicing. Handle transmission fluid safely and dispose of it responsibly.

9.1 Proper Handling of Transmission Fluid

Proper handling of transmission fluid is crucial for safety and environmental protection. Always wear gloves and protective eyewear when working with fluids. Ensure the area is well-ventilated and free from ignition sources. Use a drip pan to catch any spills during draining or refilling. Dispose of used transmission fluid responsibly by taking it to a recycling center or an authorized service provider. Never pour it down drains or mix it with other waste. Refer to local regulations for specific disposal guidelines. Keep the fluid away from children and pets. Always use the recommended 5W-50 synthetic oil to maintain optimal performance and avoid contamination. Proper handling ensures environmental safety and extends the transmission’s lifespan.

9.2 Safe Disposal of Used Fluid and Parts

Safe disposal of used transmission fluid and parts is essential for environmental protection. Always take used fluid to a certified recycling center or an authorized service provider. Never dispose of it in drains, sewers, or household trash. Used parts, such as filters or gaskets, should be properly sealed in containers to prevent leaks. Check local regulations for specific guidelines on hazardous waste disposal. Properly label containers to indicate the contents. Avoid mixing transmission fluid with other waste or chemicals. For guidance, consult local environmental agencies or contact Tuff Torq customer service. Eco-friendly disposal practices help protect the environment and comply with legal standards. Ensure all materials are handled responsibly to minimize ecological impact.

The Tuff Torq K46 transmission’s longevity relies on regular maintenance, proper oil management, and adherence to service manual guidelines. Future updates and improvements will further enhance its performance and reliability.

10.1 Summary of Key Maintenance Practices

Regular maintenance is crucial for the longevity of the Tuff Torq K46 transmission. Key practices include checking and changing the transmission fluid as recommended, typically every 100 hours, using 5W-50 synthetic oil. Cleaning and flushing the unit during servicing ensures optimal performance. Lubricating mating surfaces with oil before reassembly prevents friction and wear. Proper torque specifications during reassembly are essential to maintain structural integrity. Refer to the service manual for detailed procedures and guidelines. Always use the fill port under the black cap for draining and refilling fluid. Following these practices ensures the transmission operates efficiently and extends its lifespan. For further assistance, consult the Tuff Torq service manual or contact their customer support team.

10.2 Future Updates and Improvements

Tuff Torq continues to innovate, with plans to release updated service manuals and expand online resources for the K46 transmission. Future improvements may include enhanced lubricant recommendations and extended service intervals. The company is also exploring digital tools, such as interactive diagnostic guides, to aid users. Additionally, Tuff Torq is committed to incorporating customer feedback to refine maintenance procedures and enhance overall performance. By staying updated with the latest resources and adhering to recommended practices, users can ensure their K46 transmission remains in optimal condition. Regularly checking the Tuff Torq website for new updates and guidelines is encouraged to benefit from these advancements.